Tower Colliery Lamp Room.

Association members who were fortunate enough to visit Tower Colliery with the group during the summer of 1999 will remember it as a very enjoyable and interesting afternoon with visits to the many surface sections such as the baths, control room and winding house. Another treat was the tour around the New Level, the grading plant and washery plus the loading bunker alongside the railway line.

What we didn't see, which was a little disappointing to some members, were the underground workings and the lamp room - closed because it was a Sunday afternoon and there was no need for its services at that time.

The visit, for me, was perhaps even more of an event because I was able to meet quite a few of the society members for the first time. I was able to make the acquaintance with not only the day-trippers from the north of the country but also with some Welsh members, some of which I had met before and some that I had not. Meeting people with similar interests is always satisfying and more so when they are the friendly bunches that were gathered at Tower Colliery that particular day.

Since the visit I have had the pleasure of meeting still further members of the society; Dilwyn Evans, a member from Durham, has been a corresponding friend of mine for some time and has roots in Porth in the Rhondda Valley. Dilwyn paid a visit to Porth later in the summer and arrangements were made for a meeting of he, David Shaw and myself at the Rhondda Heritage Park. The Heritage Park is a mining museum that has been developed from the Lewis Merthyr Colliery in Trehafod. We met in the restaurant of the complex over a cup of coffee, Dave was there with his wife and Dilwyn arrived with his son. It was a double pleasure for me, to meet together Dilwyn, who was already a good friend through corresponding, and Dave whose articles in the journal have always proved so interesting and informative to me as relatively new collector. A few lamps and checks were passed around and there soon developed quite an enthusiastic debate around these items.

During that meeting also, Dilwyn explained that he would probably be traveling home via the Rhigos mountain road and would, therefore, have the, opportunity of seeing the Tower Colliery. Better than that, I was able to take the Durham visitors to the colliery where we spent some time in the Visitors Centre and were then escorted to the Control and the Lamp Rooms. It turned out to he a very informative visit with unhurried detailed information given to us about the systems in use. Dilwyn was amazed at the progress that had been made in the control of the colliery compared to how he remembered things had been in "the old days".

On relating this visit to Dave Shaw he suggested that it might he of interest to other members, especially those who were on the Tower Trip. He suggested I should write up an account of the checking system and other functions of the lamp room for publication in the journal. Hence the purpose of this article.

Lamp Room Layout

The lamp room consists of a large room with racks for holding the electric lamps, self-rescuers, miners checks and a canary cage. A smaller room houses the oil lamps and methanometers and is also used for servicing and repair of the equipment.

Checking System

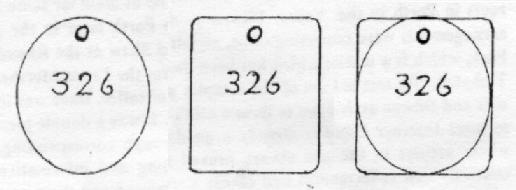

The lamp check board is housed in the large room alongside the rows of electric cap lamps. The main section of the board contains numbered checks for each miner. There are two cheeks per man, one square and one round, both 32mm in size. The miner coming on shift takes his two checks from the main section of the board and his lamp from the rack. The square check is given to the banksman before descending down the pit. The round check is carried on the minerís person during his shift underground. On ascending the shaft at the end of the shift the round check is collected by the banksman. This system, therefore, records exactly which personnel are, underground at any one time.

Lamp room personnel collect the checks from the Banksman's box at regular intervals throughout the day and return them to their respective hooks on the check board.

Checks returned to the check board are always hung with the square check behind the round one. In this way it is easy to see from the board which men are underground and which are not. If the cheeks are hung the other way, i.e. with the square check on the front, then the round check would not he visible and it could he assumed that the miner was still underground whereas in fact he may have gone home.

Illustration of hanging method used at Tower Colliery for suspending checks on the lamp room's check board.

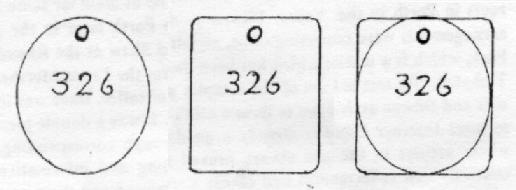

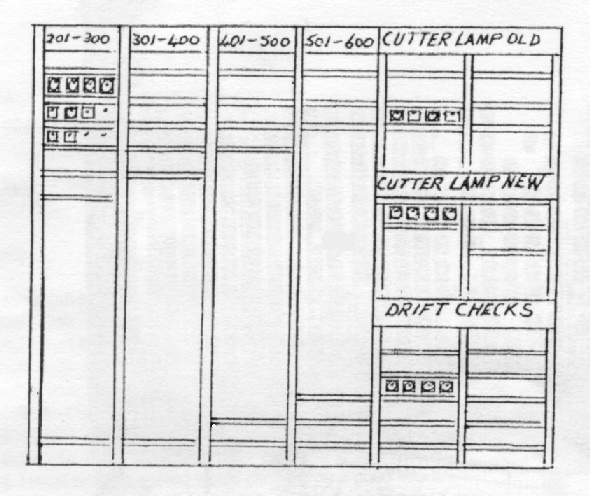

The two smaller sections of the check board are for the New Drift and for the "cutter lamps".

The New Drift is the output end of the mine and there is obviously need for personnel such as deputies and maintenance men to enter the mine via this route on occasions. Before entering the drift the miner must take a pair of discs from the "Drift" section of the board and replace them with his own checks from the main board. On arrival at the drift he then deposits the square check in a collection box and retains the round one on his person. On returning he collects the square check then replaces the pair on the "Drift" section moving his own checks back onto the main board.

Illustration of Tower Colliery's lamp room check board.

The "cutter lamp" check section of the board contains pairs of checks stamped "cutter old" or "cutter new". The cutter lamps are battery operated cap lamps with a special battery pack which allows the remote control of the coal cutter to he plugged in, thus allowing the cutter to be operated remotely front this type of lamp assembly. Regular cuttermen withdraw their cutter lamps in the same as other men withdraw their cap lamps but any non-cuttermen, such as trainees or maintenance men, must take a pair or cutter checks and replace them with his own checks. The reverse procedure applies at the end of the shift.

Tower Colliery's lamp room check board.

All checks are fabricated from brass discs approximately one millimeters thick. None of the checks are embossed and do not even carry the name of the colliery. Drift and cutter checks are stamped as such and the reason for the distinction between CUTTER OLD and CUTTER NEW checks is simply that one batch of cutter lamps is newer than the other.

Consideration is being given to extend the check sets from two to three, the additional check to be placed on the lamp rack when a lamp is taken.

Flame safety Lamps

Until approximately a year ago the type of oil lamps used by deputies and officials at the Tower Colliery were the Garfield lamps manufactured by E. THOMAS & WILLIAMS of Aberdare. These have now been replaced with ones manufactured by the Protector Lamp and Lighting Company. These new lamps are GR6S types with stainless steel bonnets.

Methanometers

These are manufactured by the Mines Safety Appliances Company, otherwise known as MSA Britain. Colliery deputies use the MSA type D6 methanometers while the workmen are provided with type AED 1.

The AED 1 is a large instrument, 25 cm high, with a red lens on the bottom. In "gas free" conditions the lamp flashes at a slow regular pace but when methane levels reach a certain pre-set level the flashing accelerates to give warning of the presence of gas. When used in most districts of the mine the instrument is set to detect methane levels greater than 2%. Normally the methanometers are suspended in prominent places within the working area so as to be readily visible. When used on FSVs (free steering vehicles) they are normally set to alarm at 1% methane levels. When working in "gassy" areas of the mine they can he set to as alarm as low as 0.8% methane levels.

The other method of gas detection that was previously used underground was the canary. A pair of canaries are still kept in the lamp room at Tower but are never used underground now, they just serve as a reminder of days gone by.

Hoping that this article will prove of interest to the members that visited Tower Colliery and maybe also to other members who couldn't make it on that day. The information was provided by the personnel at the colliery to whom I must extend my sincere thanks, in particular to Leighton who was on duty in the lamp room at the time of our visit.

Based on an article in NMMA Newsletter No.14, Summer 1999. © Alun Jones.