Investigating the "Dotto" Colliery Check

In the article "Colliery Checks: An Introduction" (see NMMA Newsletter No. 9, February 1998), David Shaw illustrated and briefly discussed a unique type of colliery check known as a "Dotto" check (4lmm diameter, brass, numbers incuse, obverse = reverse). This was the name given to such checks (Fig.1) by miners who had used them in the late 1950's and early 1960's. It is believed that the use of these "Dotto" checks was only piloted at three South Wales collieries and that they and the rather elaborate check processing system to which they belonged, had a short working life.

Fig. 1 : A selection of the enigmatic South Wales "Dotto" type pit checks.

To try and find out more about the enigmatic coded pattern of holes borne by the "Dotto" checks and the electromechanical device used to read and process them in their respective colliery Lamp Rooms, the authors decided to carry out further research.

In the first instance a correlation between the identification numbers stamped on the "Dotto" checks and the varying sequence of holes carried by them was worked out. Verification of this correlation was made possible from a sufficiently large group of differently numbered "Dotto" checks in the authors' and other private collections. The dot code carried on the checks was shown to be based on a matrix system, in which the precise positioning of the holes on each check made possible in theory, any number from 1 to 4,999 to be represented. This can be demonstrated by means of the diagrams and 'Dotto' checks illustrated below:

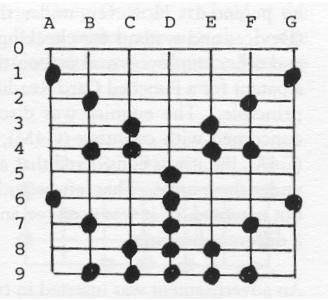

Fig.

2 : Basic seven by four matrix on which the "Dotto" check identification numbers are based.All the "Dotto" check numbers are based on a 7 (horizontal) by 4 (vertical) matrix (Fig. 2). The first key to understanding the "'Dotto" code is to accept that the top row of the dot matrix represent numbers which are multiples of a thousand. The next row down is used to represent numbers that are multiples of a hundred, the next represents multiples of ten and the final row is used to indicate single units (i.e. 0 to 9).

Fig.

3 : Representation of hole positions on the "Dotto" matrix representing the numbers 0 to 9.All numbers from 0 to 9 can be identified individually (Fig. 3). In the case of zero no dots are shown, and the horizontal axis is left empty. For the numbers 1 to 5, dot placement positions can he defined for each value. The various dot locations for this first set of numbers fill all 7 of the placement positions available on the matrix's horizontal axis. To define the dot patterns for the remaining numbers 6, 7, 8 and 9 it may he observed that the code combines the individual dot patterns for the numbers (5 + 1), (5 + 2), (5 + 3) and (5 + 4).

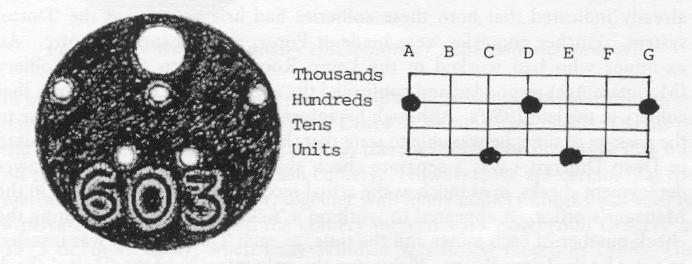

Fig.

4: "Dotto" check number "603" with corresponding number matrix.The check seen in Fig. 4 shows numbers on the 7 horizontal by 3 vertical i.e. units, tens and hundreds matrix.

It is unlikely that more than two thousand could be represented on the "thousands" line on the 7 by 4 matrix, due to the size and position of the suspension hole. Since the matrix is projected on to a curve, the holes are increasingly indented - compare the position of the outer holes representing one thousand with those representing sixty on figure 4. Some collectors have noticed several checks that have had the holes hand-drilled. This was probably done at the colliery when checks were lost or damaged, and would be easy using the required part of the matrix on other checks as a template.

Making the initial premise that a type of mechanical sensor would be required to read the pattern of holes in the check, enquiries were made at the Patent Office. We assumed that a machine developed for a specific task would indeed be patented. However, under the heading G4T and under the term TCA (Devices and systems for checking attendance and time keeping of watchmen and other employees and pigeon-timing apparatus), nothing was found except a patent for a Punched Card Reading Mechanism which probably had a similar principle. The enquiry was discussed with several other patent examiners concerned with counting (G4M), selective signalling (G4JH) and computers (G4A), but it was considered that an attendance register could not be classified under these areas. That left us with the possibility that either the machine was not patented, or it was used for another or wider purpose and classified under a different heading.

An advertisement was inserted in two of the local valley newspapers asking for any miners who had worked in the National (Wattstown) or Lady Windsor (Ynysybwl) collieries around 1960 to make contact. Earlier research had already indicated that both these collieries had briefly adopted the 'Dotto' system. Further enquiries were made at Pontypridd Historical Centre. An ex-miner who had worked in the Lamp Room at Deep Duffryn Colliery (Mountain Ash) responded and confirmed the use of "Dotto" checks also in that colliery in the late 1950's. Although his information was rather sketchy due to the passage of time he was able to state that the "Dotto" check, at least as used in Deep Duffryn, constituted a separate tallying system from that used for the usual manpower deployment. The principle difference being that in the "Dotto" system the actual check recording machine was sited in the Manager's office. It appeared to work on a "ticker tape" system, printing the check number of each miner and the time, as each "Dotto" check was inserted in a slot by the Lamp Room. If this was the only purpose of the "Dotto" check for that colliery, it would be exclusively a time check, unless further information was recorded of which we have no information. A suggestion that it was used as a wages check is unlikely, and is so far unsupported by any data. It would appear that at Deep Duffryn the usual manpower checking system still applied (each colliery's system had to he approved by the Divisional Inspector of Mines) along side the use of the "Dotto" check. The manpower deployment system employed three differently coloured light bulbs which lit up by each miner's name on the Lamp Room check board. A green light was illuminated when the miner's locker was opened, a yellow light when the lamp check was handed in and also in this particular system, a red light when the "Dotto" check was inserted in the appropriate slot. On completing the shift, the lights would be extinguished in reverse order as the checks were retrieved and the locker door relocked.

Although this explanation of the use of the "Dotto" checks was feasible, we considered that the Colliery Lodge Minutes might provide additional information (as the miners often sabotaged the checks), or the name of the machine might be mentioned. Enquiries showed that the Lodge records of the period from the National and Lady Windsor Collieries were missing from official repositories though some records from Deep Duffryn are held at the Archive Department, Swansea University. But a search through the Lodge Minutes from 1957 to 1961 and the Colliery Consultative Committee Minutes from 1958 to 1960 drew a blank.

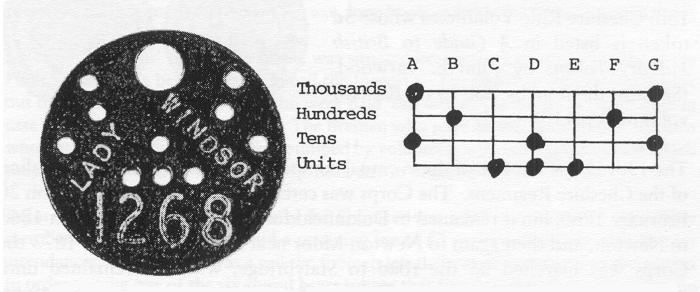

Fig.

5: Lady Windsor Colliery "Dotto" check number "1268" with corresponding number matrix.In retrospect we appear, though not as completely as we would have wished, to have confirmed the main purpose of "Dotto" as being a time check. Details of the actual machine still elude us; perhaps there was only one prototype that was on trial for a short period in each colliery. However, we are certain that the machine used at Lady Windsor, together with many colliery checks was sold to a private buyer either when the colliery merged with Abercynon Colliery in 1975 or, more likely, when Lady Windsor was finally closed in 1988. The "Dotto" check illustrated (Fig.5) is the only one seen that has a colliery name stamped on it.

In conclusion, we think that someone still has the machine as an item of interesting memorabilia!

Acknowledgements:

1) Gary Mason for the plain "Dotto" check illustration and for providing the initial impetus for this research.

2) Graham Smith for the Lady Windsor "Dotto" check illustration.

3) Pontypridd Historical Centre.

4) The Archive Department, University of Swansea.

5) Tom Evely for additional information relating to the "Dotto" checking system.

Reproduced by kind permission of the authors from their original article in Token Corresponding Society Bulletin Vol.6, No.5, Pages 182-185. © David Shaw & Mark Smith 1999.