Blundered British Mining Tokens And Colliery Checks.

As collectors of mining paranumismatics many of us may have come across the occasional check or token the design of which appears normal on first inspection but on closer scrutiny proves to be incorrect in some way. This brief article outlines some of the more notorious plus less well known of these “blundered” token examples that over the years have found their way into circulation.

As die sinkers are only human it is not surprising that very occasionally throughout history there have been token and check dies that have been cut bearing errors which, even after subsequent factory inspections and trial strikings have still found there way into use. Most such floored dies will have resulted from either visual or verbal transcribing errors made by either the manufacturers or mining companies when orders for tokens were being placed. Although such occurrences were probably rare there are still enough examples left in the paranumismatic record to attest to their existence, much to the dismay and embarrassment of both the companies that made the tokens/checks plus those that subsequently used them. Often such blundered tokens had only very short working lives before someone inevitably spotted them and they were withdrawn from use only to be replaced with new ones struck from correctly sunk dies. Inevitably such corrective actions make survivals of most blundered tokens and checks rare and hence the reason why many collectors are keen to have examples of such unusual items in their collections.

Although the first British mining tokens can be traced back to the mid to late seventeenth century, when it was quite expectable for many words to be spelt in more than one way, as far as the present author is aware the first truly “blundered” mining tokens didn’t find their way into circulation until the last half of the eighteenth century. One of the earliest such examples, described below, emanates from the large series coal carriers tokens used in the West Cumberland coalfield.

1) Windy Hill Colliery, Greysouthen, West Cumberland.

Details: A mid to late eighteenth century coal carriers token issued in the name of WINDY HILL "COLLERY". The reverse of these tokens carries the names of the pit's owners, Cookson & Hodgson. Struck in copper, 25.5 mm diameter. Manufactures & Die Sinker: Unknown.

Fig. 1: Obverse and reverse of a coal carriers token from Windy Hill Colliery - copper, 25.5 mm diameter (Davis & Water No. 165).

The obverse legend of this pre 1781 coal carriers token from Greysouthen in West Cumberland bears the misspelling of the word COLLIERY as “COLLERY” (i.e. without the “I”). As we will see later (Example No.5 below) at least one similar misspelt die to the one used above was to slip through the quality assurance net nearly two hundred years later.

The late eighteenth and early nineteenth century saw two separate revivals in the wide spread use of commercial tokens in Britain. Several leading industrialists, lead notably by Thomas Williams of the Parys Mine Company, took it upon themselves to issue their own token coinage to supplement the dearth of official coin of the realm in circulation at that time. Two of the most famous blundered mining tokens emanating from the last of these two massive token issuing periods, 1811 to 1819, are listed below.

2) West Wheal Fortune Copper Mine, Ludgvan, Cornwall.

Details: A one-penny commercial token issued in the name of WEST "WHEEL" FORTUNE Mine c.1811 to 1813. The reverse of these tokens depicts St. Michaels Mount in South-West Cornwall which would have acted as the principal port for dispatching the mine's mineral concentrate products. Struck in copper, 34 mm diameter. Manufactures & Die Sinker: Unknown but almost certainly both Birmingham based.

Fig. 2: Obverse sides of both a blundered (left) and correct version (right) of the West Wheal Fortune Mine one penny token - copper, 34 mm diameter. (Withers Nos. 693 & 695 respectively).

Rare examples of this token exist where the word “Wheal” in the token's obverse legend is misspelt “Wheel”. The die sinker can be forgiven somewhat for this transcribing error in that it is most doubtful that he would be familiar with the Cornish term “Wheal” signifying a mine (i.e. as still preserved in the more recent mine names like Wheal Jane and Wheal Martyn etc.) and so would have corrected it to the more familiar word “Wheel” which was better known to him.

Examples of these blundered tokens exist where a form of corrective action has been applied to the misspelt word "Wheal". This takes the form of an incusely over-stamp letter "A" on top of a flattened area in the obverse legend where the offending letter "E" was originally located.

Fig. 3: A corrective counter stamping in the obverse legend of a blundered West Wheal Fortune Mine penny token (Withers No. 693a).

3) Bewicke Main Colliery, County Durham.

Details: A one shilling commercial token issued in the name of "BEWICK" MAIN COLLIERY in 1811. The obverse of this token depicts a collier vessel moored along side coal staiths on the south bank of the River Tyne. Struck in silver, 25 mm diameter. Manufacture: Edward Thomason; Die Sinker: Thomas Halliday.

Fig. 4: Obverse sides of both a blundered (left) and correct version (right) of the Bewicke Main Colliery shilling token of 1811 - silver, 25 mm diameter. (Davis Nos. 4 & 5 respectively).

Examples of this token exist with the name “BEWICKE” misspelt “BEWICK”. One likely reason for this misspelling is that the die sinker was probably more familiar with the alternative spelling of the name, especially given that the pictorial design for the token, i.e. a collier vessel moored along coal staithes on the Tyne, was based on an earlier engraving of 1807 by the well known Northumberland naturalist and engraver Thomas Bewick.

Moving on into the late nineteenth and twentieth centuries we can draw on several more examples of “blundered” mining tokens from the massive series of colliery lamp, riding, and pay checks plus early miners’ association badges etc.. Several examples of these are discussed below.

4) Snydale Colliery, Pontefract, West Yorkshire.

Details:

A) N.C.B. SYNDALE COLLIERY – Double sided & uniface variations, struck as both brass and aluminium embossed types, 32 mm diameter. Maker: Possibly Henry Pasley & Son, Sheffield.

B) YORKSHIRE MINERS ASSOCIATION SYNDALE NO.1 BRANCH. – Uniface, brass, embossed, miners association badge, 28 mm by 32 mm. Maker: William Leonard, Birmingham.

An entry for Snydale (and not Syndale) Colliery near Pontefract, Yorkshire can be found in official listings of British collieries dating back to the late nineteenth century. Snydale, based on early Ordinance Survey maps, has seemingly always been the official name of the area on which the pit was sunk. This name can be found in an abbreviated form, SNY, on various N.C.B. issued checks or in full on at least one much earlier (late nineteenth century) Yorkshire Miners Association badge/check. Despite the number of check types from this colliery that carry the correct spelling of the pit's name there are at least an equal number again that can be found bearing the misspelling of the name as "Syndale". Interestingly enough it appears that confusion and misspelling of the localities name continues even today. A search of documents and listings from the Internet, carried out as part of the research for this article, revealed several sources from official histories to printed bus time tables where the name Snydale had been given as Syndale. I can find no reason for why such a misspelling has continued on and off for such a long period in history. Possibly the confusion has arisen from people confusing Snydale with the seemingly insignificant village of Syndale which is a rural community located much further north-east within the same county. To add further confusion to things there exists at least two road names within a thirty mile radius of Snydale which make reference to a "Syndale" these include Syndale Road in Cudworth near Barnsley and Syndale Road in Normanton.

Fig. 5: Obverse sides of an aluminium plus brass version of the blundered N.C.B. Snydale Colliery Pay Check, 32 mm diameter.

The most commonly encountered blundered checks from Snydale Colliery are the brass varieties of Type "A" listed above. These bear the obverse legend “SYNDALE COLLIERY” with some having a reverse legend stating "PAY CHECK NO.". Based on recent findings it is now believed that these checks were manufactured by Henry Pasley & Son of Sheffield.

Fig. 6: Obverse and reverse sides of the blundered Snydale Branch No.1 Y.M.A. membership badge/check - brass, 28 mm by 32 mm.

The blundered check Type "B", listed above, is a much earlier Yorkshire Miner’s Association badge, bearing the maker’s name William Leonard of Burbury Street, Birmingham. This piece has been issued in the name of “YORKSHIRE MINERS ASSOCIATION SYNDALE NO.1 BRANCH” and must date to the period 1887 to 1918 during which Leonard’s were operating from the address stated.

It does seem very unusual that the same spelling error occurs on two separate checks from this colliery which were made by different manufacturer some 30 to 70 years apart. Could it be that locally this pit was known at various times in history by both the names Syndale and Snydale?

5) Sutton Colliery, Nottinghamshire.

Details: A colliery lamp/riding check issued in the name of NATIONAL COAL BOARD SUTTON "COLLERY". - Uniface, brass embossed, 42 mm diameter. Maker: H.B. Sale, Birmingham.

Fig. 7: Obverse sides of both a blundered (left) and correct version (right) of the N.C.B. Sutton Colliery lamp/cage riding check - brass, 42 mm diameter.

Two die varieties of this check exist. The first and presumably later variety, bears the title “COLLIERY” spelt correctly within its legend. The second and presumably earlier type is misspelt “COLLERY” (i.e. without the “I”).

6) Snibston Colliery, Coalville, Leicestershire.

Details: A colliery lamp/riding check issued in the name of N.C.B. "SHIBSTON". - Uniface, brass embossed, oval 25 mm by 31 mm. Maker: Unknown.

Fig. 8: Obverse sides of both a blundered (right) and correct version (left) of the N.C.B. Snibston Colliery lamp/cage riding check - brass, 25 mm by 31 mm.

Two die varieties of this check exist. The first and presumably later variety, bears the colliery name “SNIBSTON” spelt correctly within its legend. The second and presumably earlier type is misspelt “SHIBSTON” (i.e. with an "H" in place of the "N"). Unlike the above Examples Nos. 5 and 6 no corrected die version of this token is known to exist.

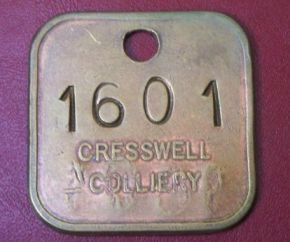

7) Creswell Colliery, North Derbyshire.

Details: An N.C.B. lamp/riding check issued in the name of "CRESSWELL" COLLIERY. - Uniface, brass embossed, check 32 mm square. Maker: H.B. Sale, Birmingham.

Fig. 9: Obverse of a blundered N.C.B. Creswell Colliery lamp/cage riding check - brass, 32 mm square.

The die used to stamp these N.C.B. colliery checks contains the misspelling of the name CRESWELL as "CRESSWELL" (i.e. with a double "S"). No corrected die version of this token is known to exist.

8) Hickleton Colliery, South Yorkshire.

Details: A colliery lamp/riding check issued in the name of N.C.B. "HICKELTON". - Uniface, brass, incusely die stamped, octagonal 34 mm by 34 mm. Maker: Unknown.

Fig. 10: Obverse of a blundered N.C.B. Hickleton Colliery lamp/cage riding check - brass, 34 mm by 34 mm.

The die used to stamp these incuse N.C.B. colliery checks contains the misspelling of the name HICKLETON as "HICKELTON" (i.e. with the "L" and "E" reversed). A corrected die version of this token is known to exist.

9) Birley Collieries - Y.M.A. Lodge, Sheffield, South Yorkshire.

Details: YORKSHIRE MINERS ASSOCN. BIRLEY COLLIERYS. – Uniface, brass, embossed, miners association badge, 32 mm diameter. Maker: Unknown.

Fig. 11: Obverse of a blundered Birley Collieries Y.M.A. lodge membership badge/check - brass, 32 mm diameter.

The die used to stamp these early twentieth century Y.M.A. lodge membership badges/checks bears a misspelling of the word COLLIERIES in the form of "COLLIERYS" (i.e. the singular form of the word has been used with the addition of an "S" at its end).

10) Comrie Colliery, Fife

Details: A colliery lamp/riding check issued in the name of F.C.C."Co." LTD. COMRIE COLLY. - Uniface, brass embossed, round 29 mm diameter. Maker: Unknown.

Fig. 12: Obverse of a blundered F.C.C. Ltd. Comrie Colliery lamp/cage riding check - brass, 29 mm diameter.

Several different Fife Coal Company Limited colliery checks are known bearing the abbreviated name F.C.C. Ltd. in their obverse legends. However, this check example has included the additional abbreviation form of the word COMPANY, i.e. as "CO." after the F.C.C. making the legend, if translated literally into its full form, read Fife Coal Company "Company" Limited. No corrected die version of this token is known to exist.

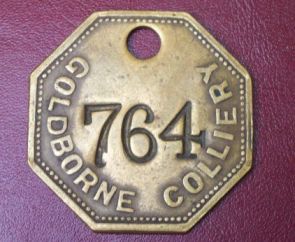

11) Golborne Colliery, Wigan, Lancashire.

Details: A post 1947 colliery lamp/riding check issued in the name of "GOLDBORNE" COLLIERY. - Uniface, brass embossed, octagonal 32 mm by 32 mm. Maker: Unknown.

Fig. 13: Obverse of a blundered post 1947 Golborne Colliery lamp/cage riding check - brass, 32 mm by 32 mm.

The die used to stamp these N.C.B. colliery checks contains the misspelling of the name GOLBORNE as "GOLDBORNE" (i.e. with a "D" added). No corrected die version of this token is known to exist.

13) Putters/Hewers Tokens by Laidler, County Durham.

Details: A putters/hewers tub identification token. - Uniface, white metal embossed, oval 22 mm by 37 mm. Maker: James Laidler & Sons of Durham City.

Fig. 14: Obverse and reverse of a putters/hewers tub identification token bearing a retrograde makers stamp of Laidler of Durham - white metal, 22 mm by 37 mm.

The makers stamp, which reads LAIDLER DURHAM, on the reverse of this putters/hewers token illustrates a fundamental die engraving or casting error. The legend on this particular token is retrograde (i.e. in reverse) due to the fact that the die sinker or in this case the cast setter has forgotten that when cutting a die or setting a casting mould its design has to be a mirror image of what is ultimately required to appear on the final token.

Acknowledgements:

I would like to thank David Shaw, Ian Coley, Jeff Thompson, Chris Matchett and John Whysall for bringing the existence of several of the above colliery checks to my attention. I would also like to thank Paul Withers, Ian Coley, Michael Finlay and Jeff Thompson for providing me with rubbings or photographs of some of the more obscure examples illustrated.

References:

1) Davis, W.J. & Waters, A.W. - "Tickets and Passes of Great Britain and Ireland". Leamington Spa. 1922.

2) Davis, W.J. - "Nineteenth Century Token Coinage". London. 1904.

3) Withers, P. & B., "British Copper Tokens 1811 - 1820". Galata Print Ltd. 1999.

4) H.B. Sale Ltd. - A list of some of the colliery checks manufactured by H.B. Sale, Birmingham on behalf of the National Coal Board. (Internal Company Document).

© Mark Smith. 2004.